1. Why is power quality a major cause of network instability in OT?

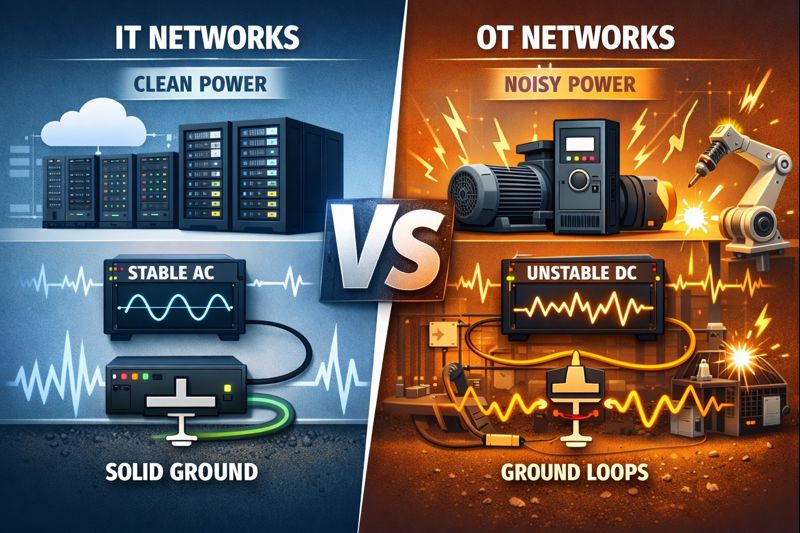

Power quality is a major cause of network instability in OT because industrial power systems are electrically noisy and subject to rapid voltage fluctuations.

Motor starts, load switching, and nonlinear devices introduce voltage dips, transients, and high frequency noise that propagate onto DC power rails. Ethernet switches depend on stable supply voltages for clocking, PHY operation, and internal logic. When power falls outside tolerance, even briefly, internal circuits may become unstable without fully failing.

In practice, this appears as intermittent link drops, unexplained CRC errors, or spontaneous reboots that correlate with machine operation rather than network load.

2. How do motor starts and VFDs affect Ethernet equipment?

Motor starts and Variable Frequency Drives affect Ethernet equipment by generating high levels of conducted and radiated electromagnetic interference.

Motor inrush currents cause voltage sags, while VFDs use high speed switching that produces broadband electrical noise in the kilohertz to megahertz range. This noise couples into power supplies, Ethernet cabling, and grounding systems, disturbing signal timing and reference voltages.

Typical symptoms include link flapping during motor start, packet corruption under load, or network faults that only occur when specific machines are running.

3. What is a ground loop and how does it impact industrial networks?

A ground loop occurs when multiple grounding paths exist between devices that are at different electrical potentials.

Instead of ground acting as a stable reference, small voltage differences cause circulating currents to flow through cable shields or equipment chassis. In Ethernet networks, these currents inject noise into the physical layer and shift signal reference levels.

This results in intermittent data errors, unstable links, and faults that are difficult to reproduce because they depend on operating conditions rather than configuration.

4. Why are industrial Ethernet switches designed for DC power?

Industrial Ethernet switches are designed for DC power because DC supplies are easier to filter, isolate, and tolerate in electrically harsh environments.

DC input designs allow wide voltage ranges, effective noise filtering, reverse polarity protection, and compatibility with battery backed systems. Industrial switches are engineered to remain operational through short voltage dips that would reset typical AC powered IT equipment.

This design improves availability and prevents unnecessary reboots during common industrial power disturbances.

5. How does electromagnetic interference affect Ethernet communication?

Electromagnetic interference affects Ethernet communication by degrading signal integrity and disrupting timing at the physical layer.

Although Ethernet uses differential signalling, strong interference can distort edge timing, corrupt symbols, and increase bit error rates. In severe cases, EMI can force auto negotiation resets or PHY reinitialisation.

In OT systems, this reduces determinism and introduces unpredictable delays that can affect control performance even when bandwidth appears sufficient.

6. What role does surge protection play in industrial Ethernet networks?

Surge protection limits transient overvoltages that would otherwise damage Ethernet interfaces and power circuitry.

In industrial environments, surges commonly originate from inductive load switching, ground potential rise, and internal power disturbances rather than lightning alone. Without protection, repeated exposure causes cumulative damage to sensitive semiconductor components.

This often results in delayed failures where equipment operates normally for extended periods before suffering permanent port or power supply damage.

7. Why are shielded cables more critical in OT than IT?

Shielded cables are more critical in OT because industrial environments continuously generate electromagnetic interference.

Cable shielding provides a controlled path for induced noise and reduces external coupling into signal pairs. Shielding is only effective when correctly terminated and grounded using appropriate industrial practices.

Incorrect shielding or grounding can worsen noise issues by introducing unintended current paths and ground loops.

8. How does improper grounding cause intermittent network faults?

Improper grounding causes intermittent network faults by destabilising the electrical reference used by Ethernet hardware.

Poor bonding or floating grounds allow noise currents to flow through unintended paths, including signal grounds and cable shields. This creates transient voltage shifts that interfere with PHY operation and data integrity.

The resulting faults are often machine dependent, intermittent, and difficult to reproduce during testing.

9. What EMC standards apply to industrial Ethernet equipment?

Industrial Ethernet equipment must comply with EMC standards that define immunity to electrical disturbances common in industrial environments.

These standards cover conducted emissions, radiated interference, electrostatic discharge, fast transient bursts, and surge immunity. Compliance ensures devices continue operating correctly in the presence of expected electrical noise.

IT grade equipment is generally tested for office environments and does not provide the same immunity margins.

10. Why do IT switches reboot unexpectedly in industrial environments?

IT switches reboot unexpectedly in industrial environments because industrial conditions exceed their power, EMC, and thermal design limits.

Voltage dips, conducted noise, and electromagnetic interference can trigger power supply protection, disrupt internal clocking, or activate watchdog mechanisms. Elevated ambient temperatures inside control cabinets further reduce operating margins.

These reboots are protective responses to environmental conditions the equipment was not designed to withstand.