1. What makes an Ethernet switch “industrial grade”?

An Ethernet switch is considered industrial grade when it is designed to operate reliably in harsh, uncontrolled environments over long lifecycles.

Key characteristics include:

- Wide operating temperature ranges (typically –40 °C to +75 °C)

- High resistance to vibration, shock, dust, and humidity

- Fanless, solid-state designs

- Redundant power inputs and wide voltage tolerance

- Industrial mounting (DIN-rail or panel mount)

- Long product availability (10–20 years vs 3–5 years in IT)

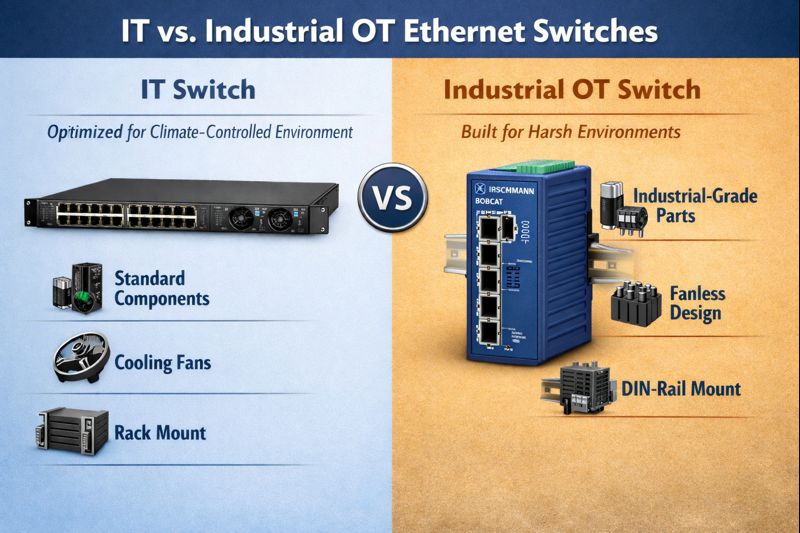

Unlike IT switches, industrial switches are engineered around availability and survivability, not peak throughput or cost optimisation.

2. How do industrial Ethernet switches differ internally from IT switches?

Internally, industrial switches differ in several critical ways:

- Component selection: Industrial-rated capacitors, regulators, and PHYs designed for temperature extremes and long MTBF

- PCB design: Thicker boards, conformal coating, and mechanical reinforcement

- Thermal management: Passive heat dissipation instead of fans

- EMC protection: Enhanced isolation and surge protection to handle electrical noise

IT switches are optimised for climate-controlled data centres; industrial switches are built assuming the opposite.

3. Why are extended temperature ratings important in OT networks?

OT environments often experience:

- Cold starts in outdoor cabinets

- Heat buildup in sealed enclosures

- Seasonal and diurnal temperature swings

Electronics outside their rated temperature range suffer from:

- Timing drift and packet errors

- Premature capacitor failure

- Sudden reboot or permanent damage

Extended temperature ratings ensure deterministic behaviour even when environmental conditions are unpredictable – critical for control systems.

4. How does vibration affect Ethernet switch reliability?

Vibration can:

- Loosen connectors and terminals

- Cause micro-fractures in solder joints

- Fatigue PCB traces over time

In industrial sites (rail, manufacturing, energy), vibration is continuous – not occasional.

Industrial switches are tested against vibration and shock standards such as those defined by International Electrotechnical Commission (e.g., IEC 60068), whereas IT switches generally are not.

5. Why do fanless designs matter in industrial environments?

Fans are one of the most common failure points in networking equipment.

Fanless designs matter because:

- Dust, oil mist, and fibres clog fans

- Fans fail mechanically over time

- Fan failure often causes thermal shutdown

By using passive cooling and solid-state designs, industrial switches dramatically increase reliability and reduce maintenance – especially in inaccessible locations.

6. What power input options are required for industrial Ethernet switches?

Industrial switches typically support:

- Wide-range DC inputs (e.g. 9–48 VDC or 12–60 VDC)

- Compatibility with control panel power supplies

- Protection against reverse polarity and surges

Unlike IT switches that expect stable AC mains power, industrial switches must tolerate dirty, fluctuating power sources.

7. Why are dual power supplies common in industrial networking?

Dual power inputs allow a switch to:

- Remain operational if one supply fails

- Be powered from independent sources or UPS systems

- Support maintenance without downtime

In OT, power redundancy is often simpler and cheaper than network-level redundancy – and far more predictable.

This design directly supports high availability, which is a core OT requirement.

8. How do DIN-rail mounted switches differ from rack-mounted IT switches?

DIN-rail switches are designed for control cabinets, not server rooms.

Key differences:

- Compact, vertical form factor

- Tool-less mounting and removal

- Designed for proximity to PLCs, drives, and sensors

- Better tolerance of vibration and heat

Rack-mounted IT switches assume stable floors, airflow, and structured cabling – assumptions that do not hold in OT.

9. Why are locking Ethernet connectors used in OT?

Standard RJ45 connectors rely on a small plastic tab – which is vulnerable to:

- Vibration

- Accidental pulls

- Repeated maintenance cycles

Locking connectors (industrial RJ45, M12) prevent intermittent disconnections that can cause:

- Network flapping

- Control interruptions

- Fault conditions in automation systems

In OT, intermittent faults are worse than hard failures – locking connectors reduce this risk.

10. What causes physical Ethernet port failures in industrial sites?

Common causes include:

- Mechanical stress from vibration or poor cable management

- Dust, moisture, or chemical ingress

- Electrostatic discharge (ESD)

- Improper grounding

- Repeated plug/unplug cycles during maintenance

Industrial switches mitigate these risks through reinforced ports, better shielding, and environmental sealing – whereas IT switches typically do not.