EtherNet/IP (Ethernet Industrial Protocol) is a widely used industrial communication protocol that operates over standard Ethernet networks. Developed by Rockwell Automation and maintained by ODVA (Open DeviceNet Vendors Association), EtherNet/IP enables real-time control and data exchange in industrial automation.

This article explores how EtherNet/IP works, its applications, its variants, and its vulnerabilities, along with strategies to address security risks.

How EtherNet/IP Works

EtherNet/IP is built on the Common Industrial Protocol (CIP), which allows it to provide:

- Real-time I/O messaging for time-critical applications.

- Explicit messaging for configuration and diagnostics.

- Object-oriented communication, enabling modular and scalable implementations.

EtherNet/IP uses standard TCP/IP and UDP/IP for data transmission and supports:

- Cyclic communication (Implicit Messaging) for real-time data exchange.

- Acyclic communication (Explicit Messaging) for parameterization and configuration.

Network Architecture

EtherNet/IP follows a producer-consumer model, where devices send data to multiple recipients instead of a strict master-slave approach. Key network components include:

- Scanner (Master Controller): Manages device communication (e.g., PLCs, DCS).

- Adapter (Slave Device): Responds to commands (e.g., sensors, actuators, drives).

- Ethernet Switches: Enable network segmentation and redundancy.

EtherNet/IP supports real-time communication using:

- TCP Port 44818 for explicit messaging.

- UDP Port 2222 for implicit messaging.

EtherNet/IP Variants

EtherNet/IP is adaptable to various industrial environments, with different implementations catering to specific needs:

1. Standard EtherNet/IP

- Uses TCP/IP and UDP/IP for communication.

- Supports star, tree, and ring topologies.

- Common in factory automation and process control.

2. EtherNet/IP with DLR (Device Level Ring)

- Provides ring redundancy for increased network reliability.

- Uses DLR-capable managed switches for seamless failover.

- Common in mission-critical applications like automotive manufacturing.

3. EtherNet/IP with TSN (Time-Sensitive Networking)

- Integrates real-time deterministic communication.

- Enhances synchronization for motion control applications.

- Reduces network latency in high-speed automation.

Applications of EtherNet/IP

EtherNet/IP is widely used across industries due to its scalability, interoperability, and real-time capabilities.

1. Industrial Automation

- Connects PLCs, HMIs, SCADA, and sensors.

- Enables real-time process monitoring.

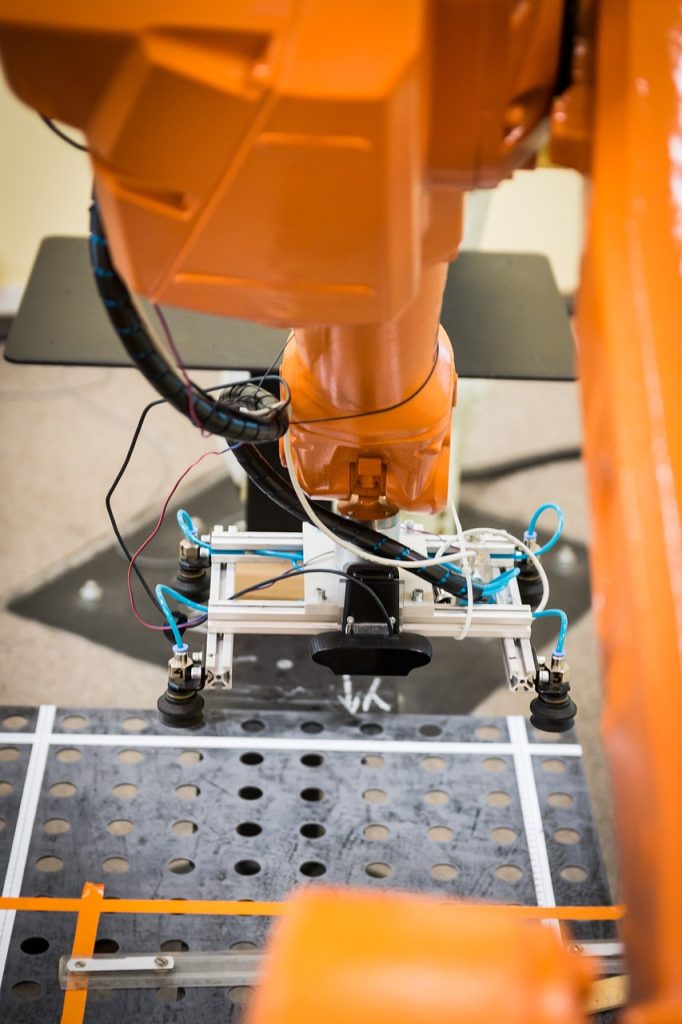

2. Robotics and Motion Control

- Supports synchronized motion and servo control.

- Used in assembly lines and CNC machines.

3. Oil and Gas Industry

- Enables remote monitoring of drilling sites.

- Ensures safe operation in hazardous environments.

4. Smart Manufacturing & IIoT

- Integrates with cloud-based analytics and predictive maintenance.

- Supports Industry 4.0 applications.

Vulnerabilities of EtherNet/IP

Despite its advantages, EtherNet/IP has several security vulnerabilities that must be addressed:

1. Lack of Built-in Security

- EtherNet/IP was not designed with cybersecurity in mind.

- No native encryption or authentication mechanisms.

2. Susceptibility to Man-in-the-Middle (MITM) Attacks

- Attackers can intercept and modify real-time data.

- Can lead to false sensor readings or manipulated control commands.

3. Unauthenticated Device Access

- Any device on the network can communicate using CIP messages.

- Potential risk of unauthorized control over industrial processes.

4. Denial-of-Service (DoS) Attacks

- Attackers can flood the network with malicious traffic, causing system slowdowns or shutdowns.

Security Measures for EtherNet/IP

To mitigate security risks, industries must implement network security best practices and leverage modern cybersecurity standards.

1. Network Segmentation & Firewalls

- Use firewalls and VLANs to isolate industrial and enterprise networks.

- Deploy Intrusion Detection Systems (IDS) to monitor network traffic.

2. Secure Authentication and Access Control

- Implement role-based access control (RBAC) to restrict device access.

- Use IEEE 802.1X authentication to verify devices before granting network access.

3. Encryption & Secure Protocols

- Deploy IPsec or TLS to encrypt EtherNet/IP communications.

- Use VPNs for secure remote access.

4. Industrial Security Standards Compliance

- Follow IEC 62443 cybersecurity standards for industrial control systems.

- Regularly update firmware and security patches for EtherNet/IP devices.

5. Implement Secure EtherNet/IP (CIP Security)

- CIP Security introduces encryption, authentication, and integrity protection.

- Uses TLS for secure explicit messaging and DTLS for implicit messaging.

- Enhances data confidentiality and network resilience.

Conclusion

EtherNet/IP is a powerful and flexible industrial communication protocol, widely used in manufacturing, automation, and process control. However, its lack of native security features makes it vulnerable to cyber threats.

By implementing secure network practices, authentication mechanisms, encryption, and CIP Security, industries can protect EtherNet/IP networks from cyber attacks while maintaining high performance and reliability.

As industrial systems become more connected, securing EtherNet/IP in Industry 4.0 environments will be crucial to ensuring safe and efficient automation.