1. What is the difference between IT networks and OT networks?

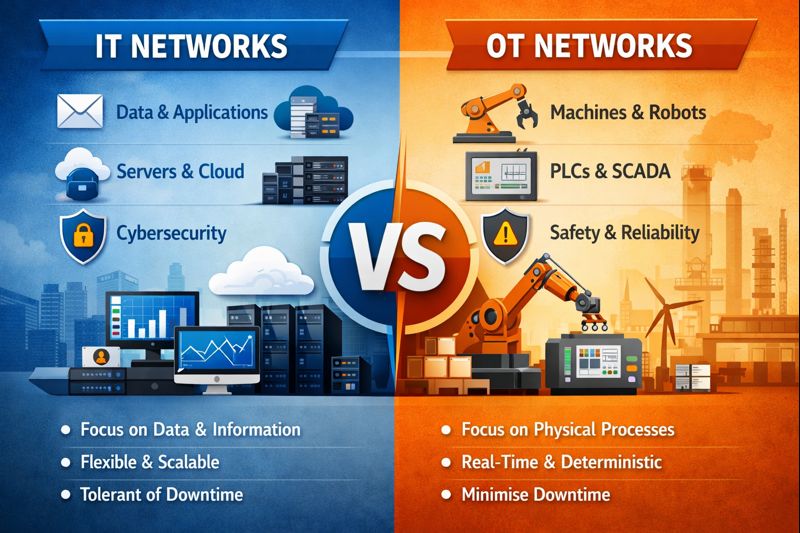

IT networks are designed to move, store, and process information such as emails, databases, ERP systems, and cloud workloads. Their primary objectives are throughput, scalability, and user access.

OT networks are designed to control physical processes. They connect PLCs, sensors, actuators, drives, robots, and safety systems that directly influence machinery and infrastructure.

The key difference is impact.

Failures in IT systems usually affect productivity or data access.

Failures in OT systems affect production continuity, equipment integrity, and human safety.

2. Why were IT networks and OT networks historically separated?

OT systems existed long before Ethernet became common in enterprises. Early control networks were proprietary, serial, and purpose-built for deterministic behaviour.

Separation was maintained because:

OT required predictable timing and stability

IT networks evolved rapidly with frequent changes

Cyber risks in IT could cause physical damage in OT

Maintenance windows in IT were incompatible with 24/7 industrial operations

Physical and logical separation reduced operational and safety risks.

3. What problems arise when IT networking principles are applied directly to OT?

IT networking assumes:

- Traffic can be buffered or retried

- Delays are acceptable

- Congestion is normal

- Networks can reconverge slowly

In OT, these assumptions cause:

- Control loop instability due to unpredictable delays

- Production stops during spanning tree or routing reconvergence

- Packet inspection or security scans interrupting real-time traffic

- Firmware updates or reboots causing unplanned outages

What is acceptable inconvenience in IT becomes operational failure in OT.

4. How do IT and OT networks differ in failure tolerance?

IT networks are designed to fail gracefully. Applications retry, users reconnect, and services resume after seconds or minutes.

OT networks often have near-zero tolerance for failure. Even brief interruptions can:

- Stop production lines

- Trigger emergency shutdowns

- Damage equipment mid-process

- Cause safety system faults

OT networks must be engineered to avoid failure, not recover from it.

5. Why is availability prioritised over performance in OT systems?

In industrial environments:

- A slightly slower network that runs continuously is acceptable

- A fast network that occasionally fails is not

Downtime directly translates to:

- Lost production output

- Scrapped materials

- Contractual penalties

- Safety incidents

As a result, OT design prioritises continuous availability and predictability over raw bandwidth or peak performance.

6. How does network recovery time differ between IT and OT environments?

IT environments typically accept recovery times measured in seconds or minutes. Routing protocol convergence, spanning tree recalculation, or service restarts are normal.

OT environments often require:

- Recovery times in milliseconds

- Or no visible recovery event at all

Industrial Ethernet designs use ring topologies, media redundancy, and fast failover mechanisms specifically to meet these constraints.

7. What does “deterministic networking” mean in industrial Ethernet?

Deterministic networking means that:

- Messages arrive within a guaranteed time window

- Latency is predictable

- Jitter is tightly controlled

- Traffic behaviour is known in advance

Unlike best-effort Ethernet, deterministic networks behave in a repeatable and measurable way, which is essential for real-time control.

8. Why is determinism critical for industrial control systems?

Industrial control relies on closed-loop feedback:

- Sensors measure a physical variable

- Controllers calculate a response

- Actuators execute that response

If timing varies unpredictably, the control loop becomes unstable. This can cause:

- Oscillation

- Incorrect actuation

- Mechanical stress

- Unsafe operating conditions

Determinism ensures the control logic behaves exactly as designed.

9. How do latency and jitter affect OT systems differently than IT systems?

In IT systems:

- Latency reduces user experience

- Jitter causes minor quality issues (e.g. video buffering)

In OT systems:

- Latency delays control decisions

- Jitter breaks synchronization between devices

- Timing variation can corrupt motion control and process accuracy

OT systems depend on consistent timing, not just low average delay.

10. Why is packet loss unacceptable in many OT applications?

Many OT protocols assume packets will arrive exactly when expected. Packet loss can result in:

- Missed control commands

- Invalid sensor data

- Loss of synchronization

- Triggered fault states or shutdowns

Retransmissions often arrive too late to be useful. As a result, OT networks are designed to prevent packet loss, not recover from it.